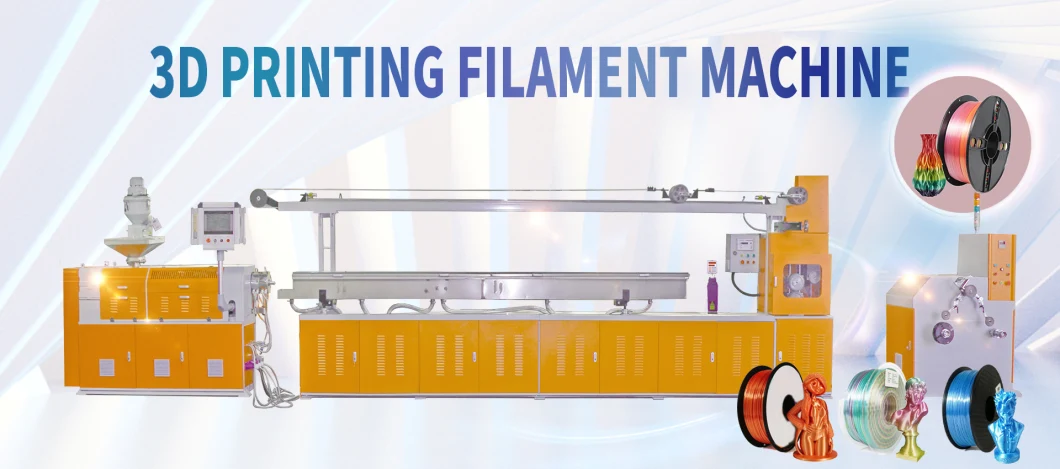

3D Printer Filament Making Machine PETG PLA Filament Extrusion Line Peek Filament Production Line

Description

Basic Info

| Model NO. | GSD 45 |

| After-sales Service | Yes |

| Warranty | 1 Year |

| Type | 3D Printer Filament Extruder Machine |

| Plastic Processed | PLA Pbs |

| Product Type | Granulating Extruder |

| Feeding Mode | One Feed |

| Assembly Structure | Separate Type Extruder |

| Screw | Single-Screw |

| Engagement System | Full Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Custom | Yes |

| Usage | 3D Printer Filament Making Machine |

| Material | PLA PETG ABS Peek |

| Machine Name | 3D Printer Filament Making Machine |

| Guarantee | One Year |

| Overseas Installation | Yes |

| Machine Condition | Brand New |

| Screw Design | Single Screw |

| Machine Capacity | 1-50kg/H |

| L/D | 32:1 |

| Machine Color | Customized |

| Motor Brand | Sienmes/ Wn |

| Inverter | ABB/ Delter |

| Name | 3D Printer Filament Making Machine |

| Raw Material | PETG PLA Peek ABS |

| Transport Package | Sea, Air and Land Transport |

| Specification | custom |

| Trademark | yes |

| Origin | China |

| Production Capacity | 50kg/H |

Product Description

product description

3D printing is a revvolutionary technology since it began, which has became more and more popular for all kinds of industries. With the rise of 3D printing technology, our company developed the filament machine for 3D printing, and sold them to a lot of developed countries, such as France,UK,USA,Russia and so on, which had been very well received.

Machine Composition

| Item | Equipment line | QTY/SET |

| 1 | Mixer | 1 |

| 2 | Vacuum Loader | 1 |

| 3 | Hopper dryer | 1 |

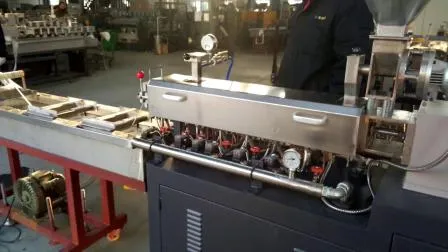

| 4-1 | Single screw extruder | 1 |

| 4-2 | Die head | 1 |

| 5 | Water tank | 1 |

| 6 | Tractor machine | 1 |

| 7 | Storage thread stand | 1 |

| 8 | Filament Diameter Laser | 1 |

| 9 | Winding machine | 1 |

| 10 | Vacuum Packing machine | 1 |

1. Mixer

------Mix the raw material with the color masterbatch or color powder

------Capacity:50kg/batch

------Motor power:1.5kw

------Material: S/S

------Time:8-10/batch

2.Vacuum Loader

------Model:1.1KW/1.5HP 1Φ

------Capacity:350kg/h

-------Loading distance:6-8m

-------Pipe Diameter:Φ38(mm)

-------Material Storage:7.5L

3. Hopper Dryer

------Volume:50L

------Heating power: 4.5kw

------Features:Protect the fan and electrical heated tube automatically.Adopting famous brand electrical components,reliable performance,material of heating tube is SUS304 stainless steel,no pollution,have long performance life.The body sealing are made of silicone rubber for thermal insulation

4-1 Single Screw Extruder

------Diameter:Φ45mm

------L/D=32:1

------Material of screw: 38CrMoALA

4-2 Die head

------Material 38CrMoALA,inner surface with precision polishing after hard chrome plating

------Mold structure:adopts high pressure volumetric mold,meet the high speed/precision production requirements

------Mold heater:Stainless steel heater Voltage plug:security against leakage protection plug

This mold can process both 1.75 and 3.0 diameters, because we just have to adjust the tractor speed. We do not need two molds.

5. Water Tank

------Hot water tank 1.5 meter(with heating device) , Cold water tank 3.5 meter

------water tank specification;sus304 stainless steel materials,stainless plate thickness 2.0mm

Fore and back moving of water tank

------Circulating water system:direct-coupled centrifugal pump 0.75kw 1set;circulation water tank,material sus304,built-in float ball liquid level control switch,can form cooling water circulation system with chiller

------Water inlet;1 1/2'',stainless steel stop valve

------Water outlet:1 1/2",stainless steel stop valve

------Cooling way:Immersion bath cooling,tank inside equipped with eight groups guiding wheel

------Operation control box:vacuum pump start/stop;Handling speed display and adjust button;Table fore and back moving button;Emergency stop button.

6. Tractor Machine

------Outside of gear movement mechanism installed with organic glass protective cover

------Line speed setting:0-100m/min(Can be set according to production)

------Driving motor:"servo" motor

------Counter device:Japan"OMRON" series incremental type rotary encoder

------Puller with the following function:Start/Stop,E-stop,hauling speed display,hauling speed regulation.

Abnormal situation alarming

7. Storage Thread Stand

--------Length: 6m

8.Filament Diameter Laser

-----The Laser Diameter Guage is a high and new-technological product incorporating optics and electrics together. By adopting the laser scanning method, the instrument can carried out high-speed, high-precision, non-contact type measurement of objects to be measured on the production line. Owing to the non-contact type measuring point, no interference will be introduced to the measured object. Thus this instrument is especially applicable to hot, soft, movable and vibrating measured objects.

-----Measuring Range:0.0500~50mm

-----Tolerance:±3μm

-----Repeatability Error:±1μm

-----Resolution:0. 0001mm

-----Scanning speed:1800times/s

-----Data processor and data preservation:High performance DSP processor is adopted for high-speed and high-precision calculation; large capacity FLASH memory is adopted for convenient data recording.

-----Communication interface:RS232 or RS485 communication interface can be connected with a computer for on-line detection, which can also be used to transimit measured records saved into the computer.

-----The laser will automatically and continuously send the data to the PLC program, the program will then automatically control the cooling water temperature and other systems to control the tolerance.

9. WindingMachine

------Working speed:max 200m/min

------Rolling up tooling quantity:Double position winding axle

------Rolling up motor:frequency motor/driver*2 sets(Independent driving for each position)

------Automatic traversing device:The linear guide traversing device guide wheel.

------Driving of traversing device:through synchronous transmission mechanism to keep the same displacement rate with roll plate revolving speed.

------Tension induction regulator:Automatic regulating winding speed and traversing speed according to tension state of pipe.Apply to soft pipes,keep winding under natural relaxation state,when tension condition change,the fluctuation within manageable scope,avoid pipe over drew by too fast winding speed and too slow speed of winding.

------Regulator support:Aluminum alloy support

------Control panel:Power stat/stop switch,winding speed manual/auto rotary switch,winding speed adjust knob,meter counter,counting alarm lamp,power indicator,E-stop button.

10. Vacuum Packing Machine

According to different needs, this line can use 1KG, 2KG, 3KG, 4KG, 5KG spool.

Prev: 3D Printer Filament Extrusion Line PLA Filament Making Machine PETG ABS 3D Filament Production Line

Next: Automatic Plastic Film Coating Laminating Machine with Round Knife

Our Contact