High Temperature Peek/Pei/Carbon Fiber 3D Filament Extrusion Line

Description

Basic Info

| Model NO. | PL |

| Engagement System | Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Screw Design | Single Screw |

| Screw Diameter | 25mm, 35mm, 45mm |

| Color | Customized |

| Cooling Type | Water Cooling |

| Raw Material | Pet, Peek, PLA, PC, ABS, Nylon |

| Final Product | Filament |

| Usage | 3D Printer Filament Extrusion |

| Filament Dia. | 1.75-3mm |

| Tolerance Control | 0.02-0.03mm |

| One Spool Weight | About 1kg |

| Whole Line Length | 12.5meters |

| Whole Line Weight | 2t |

| Installed Power | Around 20kw |

| Main Motor Power | 5.5kw |

| Capacity | 20-30kg/H |

| Transport Package | Standard Pacakge |

| Specification | It depends |

| Trademark | Plastar |

| Origin | China |

| HS Code | 84772090 |

| Production Capacity | 1000sets/Year |

Product Description

3D Printer Filament Extruder Making Machine is mainly used to produce high quality ABS/PLA/PETG/PEEK/PEI/Carbon fiber filament for all brands of 3D printers. This 3D Printer Filament Extruder/ Extruding Machine has high output and and performance. It can produce filament with diameter of 1.75 and 3mm. We use laser gauge in the 3D Printer Plastic Filament extruding line to measure the diameter and control the tolerance within ±0.02mm.

Introduction of 3D printer filament extruding machine:

3D Printer extrusion machine is a device which can "print" the 3D object, function as the laser forming technology, adopts the hierarchical processing,principle of superposition forming, through increased material step by step stack to generate 3D entity. 3D printing technology is not very complicated itself, but the available consuming materials was a difficulty. Ordinary printer consumables is ink and paper, but the 3D printer consumables are mainly plastic and other powder, and must through special processing, also high requirement of the curing reaction speed 3D printer is a device which can "print" the 3D object, function as the laser forming technology, adopts the hierarchical processing, principle of superposition forming, through increased material step by step stack to generate 3D entity.

Build Your Own 3D Filament production factory With UsOur 3D Printer Filament Extrusion Machine is equipped with diameter automatic feedback system.1,Application:The Filament Extruder Machine is used to make 3d printer filament,The filament is widely used in many different industries,such as mould making,Shoes, industry designing, as well as medical.2, Speficication of our extrusion line:1. Higher capacity compared with other suppliers same model extrusion line.2. Low tolerance:+/-0.02mm, even+/-0.01mm.3. It can produce different diameter filaments from 1.75mm-3.0mm.4. Easy operation: PLC full-automatical control system.5. Produce different raw material: ABS PLA PA HIPS PETG PEEK PCL etc.6. We can provide installation services overseas

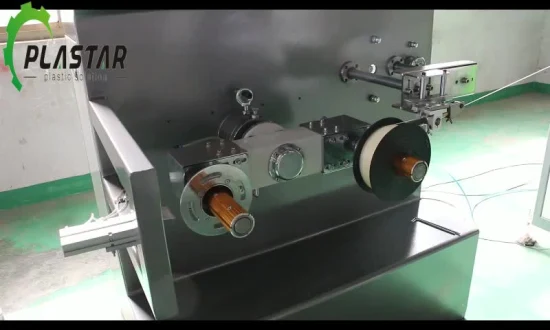

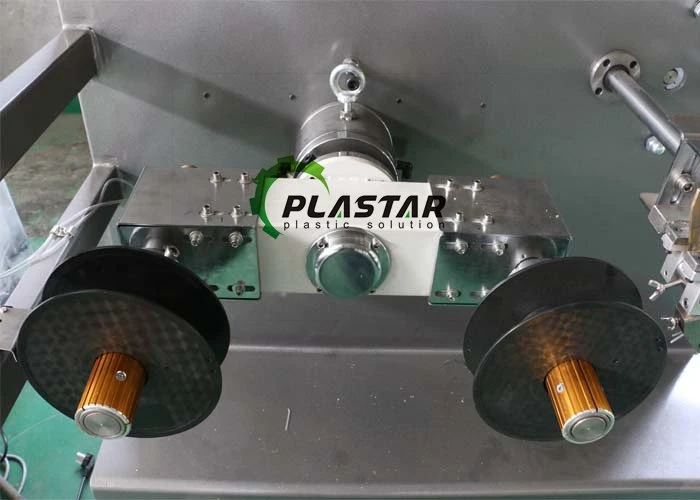

---Our 3D printer filament line is equipped with our 5th generation new type double disc winding machine, this new generation rotatable double disc winding machine is designed and produced by our company, it is our 5th generation winding machine, compared with traditional single disc or old type double disc winding machine, the new double disc Auto winding machine can shorten the spool changing time to not more than 25 sec.

This new design winding machine can really save time and improve efficiency, when spool 1 is full, it can automatically rotates into spool 2 position, at same time, empty spool 2 will be in the postion of spool 1, the workers cut the filament, and feed the filament into spool 2, the winding machine keeps working when the worker takes the full spool out.

---Our filament extrusion line adopts PLC automatic PID control system, the diameter of the filament does not need manual adjustment, the PLC system can automatically control and adjust the diameter of the filament, at the same time, we can also add remote control system if customer needs it.

---The application of 3D printer filament

Based on the analysis of the characteristics and performance of different structures of 3D printers and consumables, we have a clear understanding of the working principle of 3D printers. We believe that plastic materials will remain the mainstreammaterial for 3D printing for a long time.

We have different machine models with different capacity for your choice:

| Model | Power | Diameter | Capacity | Tolerance | Material |

| PL-25 | 2.2 KW | 1.75mm-3mm | 3-5Kg/h | +0.02mm | PLA ABS HIPS PA PET Nylon PP |

| PL-30 | 4 KW | 1.75mm-3mm | 10-15Kg/h | +0.02mm | PLA ABS HIPS PA PET Nylon PP |

| PL-45 | 7.5 KW | 1.75mm-3mm | 20-25Kg/h | +0.02mm | PLA ABS HIPS PA PET Nylon PP |

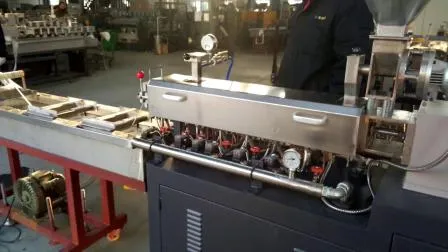

This Filament Extruder Machine is composed by following parts:

| No. | Item | Qty |

| 1 | Hopper Dryer | 1 Set |

| 2 | Single Screw Plastic Extruder | 1 Set |

| 3 | Die | 2 Sets |

| 4 | Hot & Cooling water cooling tank | 2 Sets |

| 5 | Horizontal storage rank | 1 Set |

| 6 | Backstop machine | 1 set |

| 7 | Haul-off machine | 1 set |

| 8 | Winding machine | 1 set |

High Precision PLA ABS 3D Filament Extruder Machine pictures for reference:

Commercial Details:

Payment: Deposit 40% contract into valid, delivery against payment of 60% balance after qualified acceptance;

Leave factory testing: Before leaving factory, equipment should be tested by both parties. Test material offered by buyer;

Installation and debugging: We will send 1-2 technicians for machine's installation and debugging according to customer's requirement: The technicians' board and lodging and the round-trip airplane ticket expense undertaken by the buyer, additional service charge USD80. for each technician / one day, estimate 2-3 working days.

Guarantee period: Guarantee period is 12months after leaving factory, damaged parts caused by quality problem is changed for free during guarantee period. Maintenance Technicians' board and lodging and the round-trip airplane ticket expense undertaken by the buyer, but without service charge.

Service after sale:

- Service is available lifelong. Maintenance technicians' board and lodging and the round-trip airplane ticket expense undertaken by the buyer. After 12months guarantee period over, should pay additional service charge USD80.00 for each Technician / one day;

- will response any inquiry within 24 hours and it will be solved as soon as possible;

can offer training customer's engineers for free; will send enough technicians to the Buyer's company for installation and testing the lines.

Our Contact