Lab Twin Screw Extruder Compounding Extruder for Polymers, Plastic

Product Description The lab twin screw extruder machine is suitable for mixing and processing experiments of engineering

Description

Basic Info

| Model NO. | XH-433 |

| Automation | Automatic |

| Computerized | Computerized |

| Customized | Non-Customized |

| Certification | CE, ISO9001:2008 |

| Condition | New |

| Applicable Materials | PP, PE, PS, Pet, TPE, etc. |

| Screw Diameters | 21.7mm |

| Screw Speed | 0 - 300rpm |

| Screw L/D Ratio | 1:40 |

| Output | 1 - 10kg/H (Decide by Formula) |

| Cooling Device | Air/Water Cooling |

| Cutting Device | Granulator |

| Power Supply | 380V/50Hz/3 Phases or Customerized |

| Control Mode | Siemens Touching Screen PLC Control |

| Transport Package | Wooden Case |

| Trademark | Xihua |

| Origin | China |

Product Description

The lab twin screw extruder machine is suitable for mixing and processing experiments of engineering plastics, modified plastics, waste plastics and masterbatches. It has homogeneous, plastic coloring, filling modification functions.Under the action of heating, mixing, shearing, plasticizing and compacting the exhaust, the material is plastified into a uniform melt, and extruded under the twin screw extruder for plastic pelletsand extruded through the nose into round strips. The long strips after being cooled by water in the cooling water tank or after being air-cooled, then pelletized by a pelletizer to obtain plastic pellets.

| XH-433-20 TWIN SCREW EXTRUSION LINE | |

| Applicable materials | PP, PE, PS, PET, TPE, etc. |

| Screw diameters | 21.7mm |

| Screw speed | 0 - 300rpm |

| Screw L/D ratio | 1:40 |

| Output | 1 - 10kg/h (decide by formula) |

| Cooling device | air/water cooling |

| Cutting device | Granulator |

| Power supply | 380V/50Hz/3 phases or Customerized |

| Control mode | SIEMENS Touching Screen PLC control |

Main Features

1) Adopting international brand variable speed control motor to precisely control the screw rotating speed;

2) The 3D processed geometry screw elements maintain uniform gaps and achieve very good self-clean and precise plasticizing effect;

3) Using parallel two-axis high speed high torque gearbox to make the extruder applicable for more than 95% materials' compounding and extrusion technologies;

4) Emergency stops and devices to protect safety of the operator;

5) Optional side feeder for special materials, e.g. glass fiber;

6) Optional forced feeder to increase stability of feeding;

7) Optional liquid feeding equipment;

8) Optional gravimetric feeder

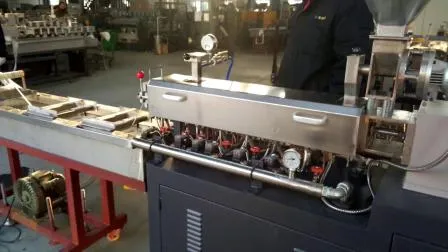

Detail images

Testing sample

Prev: Hot Sale Multi-Functional Lab Scale Twin Screw Extruder

Next: Nanjing Mini Micro Compounding Desktop Small Lab Plastic Twin Screw Extruder Recycle Polymers

Our Contact

Send now