Online Inspection Rewinding Machine Printing Machine Laminating Machine Coating Machine Flexo Printing Machine Cutting Machine Packing Machine Rewinder

Online Inspection Rewinding Machine Printing Machine Laminating Machine Coating Machine Flexo Printing Machine Cutting M

Description

Basic Info

| Model NO. | HN1300R |

| Packaging | Exporting Wooden Box |

| Classification | Rewinding |

| Applicable Process | Final Inspection |

| Suitable Substrates | Film Paper Labels |

| Packaging Material | Exporting Wooden Box |

| Inspection | Online |

| PLC | Mitsubish |

| Servo Motor | Fukuta |

| Color | White |

| Speed | 300m/Min |

| Web Width | 1300mm |

| Power | 380V 50Hz |

| Installing | No Need |

| Stroboscope Lamp | 1 Set |

| Camera | Colours |

| Lead Time | 25 Days |

| Transport Package | Subject as Per The Real Machine |

| Specification | subject as per the real machine |

| Trademark | HAVESINO |

| Origin | China |

| HS Code | 8441100000 |

| Production Capacity | 20PC/Month |

Product Description

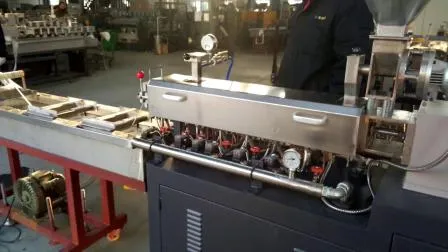

Online Inspection Rewinding Machine Printing Machine Laminating Machine Coating Machine Flexo Printing Machine Cutting Machine Packing Machine RewinderHN1300R INSPECTION REWINDING MACHINE Film/Foil/Non-Woven/Label/Lamination Material Slitter RewinderHAVESINO Materials to Machine

Click One you interested

APPLICATION REWINDING AND INSPECTING THE MATERIAL FROM 12-1500um PET,BOPP,CPP,LAMINATION MATERIAL OTHER PRINTED FILM AND FOIL. BASIC INFORMATION

| PART A: REWINDING MACHINE SPECIFICATION | ||

| 1 | REWINDING WIDTH | 300mm-1600MM |

| 2 | REWINDING THICKNESS | 12-250UM |

| 3 | UNWIND DIA. | MAX1000MM |

| 4 | UNWIND CORE I.D. | SHAFTLESS 3 INCH AND 6 INCH |

| 5 | REWINDING DIA. | MAX 1000MM |

| 6 | REWINDING CORE I.D | SHAFTLESS 3 INCH AND 6 INCH |

| 7 | MECHANICAL SPEED | MAX500M/MIN |

| 8 | WORKING SPEED | MAX400M/MIN |

| 9 | MACHINE FRAME THICKNESS: | 50MM |

| 10 | METER COUNTER: | METER COUNTER |

| 11 | POWER SOURCE | 380V±10%,3 PHASE 4 WIRES,50Hz |

| 12 | PNEUMATIC SOURCE | MINI 0.6MPA |

| 13 | N.W/G.W (REF. ONLY): | 4500/4800 KG |

| PART B: PRINTING INSPECTION SYSTEM SPECIFICATION | ||

| 1 | INSPECTION WIDTH: | 300MM-1500MM |

| 2 | INSPECTION SPEED: | 300M/MIN |

| 3 | INSPECTION ACCURACY: | 0.10MM² (CONTRAST ≥ 20) |

| 4 | MINI THREADINESS SIZE: | 0.10MM × 5MM(CONTRAST ≥ 20) |

| 5 | MINI PRINTING REGISTRATION DEVIATION: ±0.10MM | |

FUNCTIONAL DESCRIPITION PART A: REWINDING MACHINE 1 With 3" and 6" chuck, the machine can rewinding both 3" core and 6" core jumbo roll; 2 With Hydraulic Lifter, the machine can load the jumbo roll up easily and conveniently; 3 Work together with Online Printing Inspection System, the machine can stop automaticly when find the defect printing point; 4 Automaticly tension control; 5 With edge guider, it can help to rewind the roll more smooth and neat;

PART B: PRINTING INSPECTION SYSTEM

1 The Inspection System can find the defect of the printing in real time, the operator can decide if it is needed to remove the defect point or not by control the machine; 2 It is compatible inspection of pure material, aluminum laminted film and printing film can be inspected at same time, do not need any adjustment manually. 3 The inspection system works together with the rewinder, can loated the defected point by controling the rewinding machine, and stop the defect point on the light tabel. 4 Optional Off-line Unit: it can find the defect point automaticly through the data from other inspection system.

About HavesinoHAVESINO is one of top suppliers for Semi Automatic and Fully Automatic thermal paper slitter re-winders and converting machinery for more than 12 years. We have in excess of hundreds of machine installations all around the world!HAVESINO is one of the leaders in design, developing and building of quality,high performance of thermal paper slitter re-winders and the support machine such as core loader, core-less machine and fully automatic packing lines.

GUARANTEE AND SERVICE

1 100% Test and Check Before Shipment. 2 Detailed Instruction Manual. 3 One Year Guarantee for All Key Parts. 4 Installing and Operator Training Service Provided. 5 Whole-Life Free Technical Support. 6 Regular On-Site Routine Inspection.

Our Contact

Send now