Plastic Laminating Coating Machine Paper Laminating Machine

Description

Basic Info

| Model NO. | GS |

| Assembly Structure | Integral Type Extruder |

| Screw | Single-Screw |

| Engagement System | Full Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Custom | Yes |

| Transport Package | Shipping |

| Specification | custom |

| Trademark | yes |

| Origin | China |

| Production Capacity | 1200kg/H |

Product Description

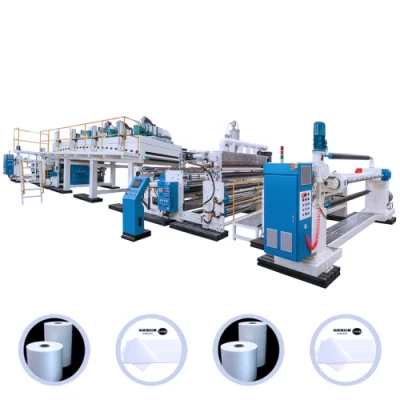

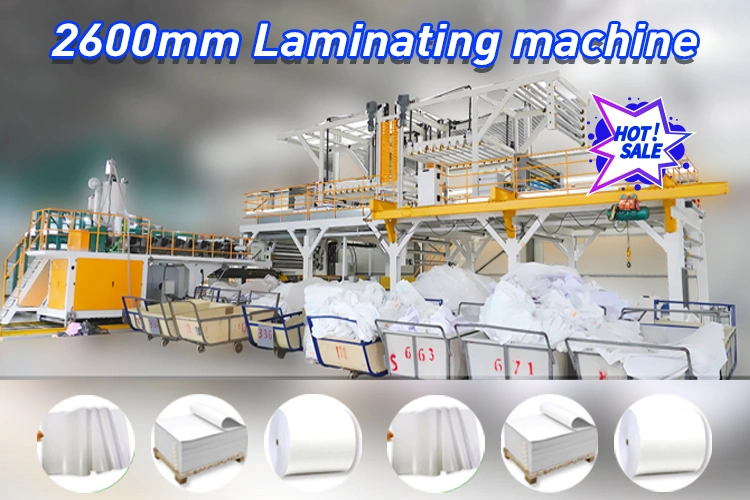

Plastic Laminating Coating Machine Paper Laminating Machine

Product Processing:

After the plastic is melted, it is extruded in a high-temperature molten state with paper, kraft paper, non-woven fabric, aluminum foil, lining cloth and other series for high-speed coating composite to achieve the ideal tensile strength, compactness, barrier property, and improve the moisture resistance of the material .Advantage:

- Adopt double-station automatic reeling and changing device

- Magnetic powder tension design

- Constant tension control

- Production acceleration and deceleration can be controlled by synchronous ratio

- Online scrap recycling system

- The speed can reach 50m/min, 100m/min, 150m/min.

Machine Size and Model:

Paper lamination machine

Kraft Paper lamination machine

Non-woven fabric lamination machine

Aluminum foil lamination machine

Interlining lamination machine

| Machine specifications | 1200/1400/1700mm |

| Effective width | MAX 1100/1300/1600mm |

| Mechanical speed | 300m/min |

| Screw diameter | GSD-100mm/GSD-115mm |

| Extrusion | MAX 400kg/h or 550kg/h |

| Use resin | LDPE/PP/PBS/PLA |

| Coating thickness | 15~45μm |

| Rewinding and unwinding diameter | Unwind MAXφ1500mm; Winding MAXφ1800mm |

| Use substrate | Paper(100~400g/) |

| Dimension (Length×width×height) | Double sided:30.7×(9.5~11)×3.8m |

| Single side:21.5×(9.5~11)×3.8m |

Production Processing:

| 1.0 | A double station unwinding system | 1 set |

| 2.0 | Screw feeding device | 1 set |

| 3.0 | Hopper dryer | 1 set |

| 4.0 | Extrusion Model SJ-90*32 | 1 set |

| 5.0 | Single board single station filter | 1 set |

| 6.0 | Solution static mixer | 1 set |

| 7.0 | 1250mm Laminating Special Mould | 1 set |

| 8.0 | Laminating composite molding system | 1 set |

| 9.0 | X automatic measure thickness device | 1 set |

| 10.0 | B double station unwinding system | 1 set |

| 11.0 | Correction device | 1 set |

| 12.0 | Fabric static elimination device | 1 set |

| 13.0 | LED lighting observation device | 1 set |

| 14.0 | Shearing pneumatic cutting knife set | 1 set |

| 15.0 | Edge air conveying device | 1 set |

| 16.0 | Tractor | 1 set |

| 17.0 | Double station automatic winding system | 1 set |

| 18.0 | SIEMENS Control System | 1 set |

Components and Descriptions

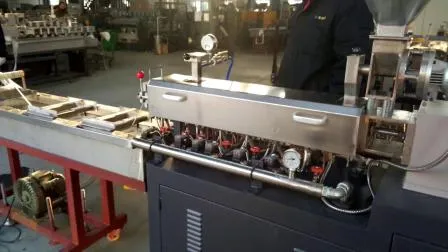

Mainly screw extruder:The extruder adopts the special screw design of the company's laminating machine. It is characterized by low calorific value, good plasticization, less fine points and superior products for PP/PE materials.

screw diameter: φ90

Aspect ratio: 32:1

Structure: Single screw

Heating power: 40KW.

Deceleration machine: Hard tooth surface made of alloy steel after repeated heat treatment. The tooth surface is specially ground to ensure stable operation, low noise, and circulating cooling device.

Main engine: Simense Motor

Rated power: 90KW

Host frequency conversion: ABB inverter

Single Board Single Station Filter

After the filter plate is produced for a period of time, the plastic melt enters the flow channel, and when a predetermined pressure difference is formed, the mesh should be changed. The net change work pushes the ram to move accordingly through the hydraulic system, prompting the filter plate to exit the working position while the other filter plate enters the working position, and then opens the protective cover when stopping the movement. Use the tool to quickly clean the melt around the gate and the filter hole, remove the old filter mesh, and replace it with a new one to complete the job. This machine is equipped with a network front pressure sensor and display to monitor the blockage of the filter to ensure timely network change. The friction pair of the screen changer is made of high-hardness and wear-resistant material to ensure long-term use.

Solution Static Mixer

The energy-efficient static mixer has a special structure of mixing elements, which are composed of a plurality of intersecting steel bars (bars) arranged at right angles, separated by a 45 degree angle, so that the melt flowing through is divided and merged multiple times. The orientation is changed to further promote the uniform dispersion and plasticization of the melt. It is usually used in extruders with very high precision requirements.

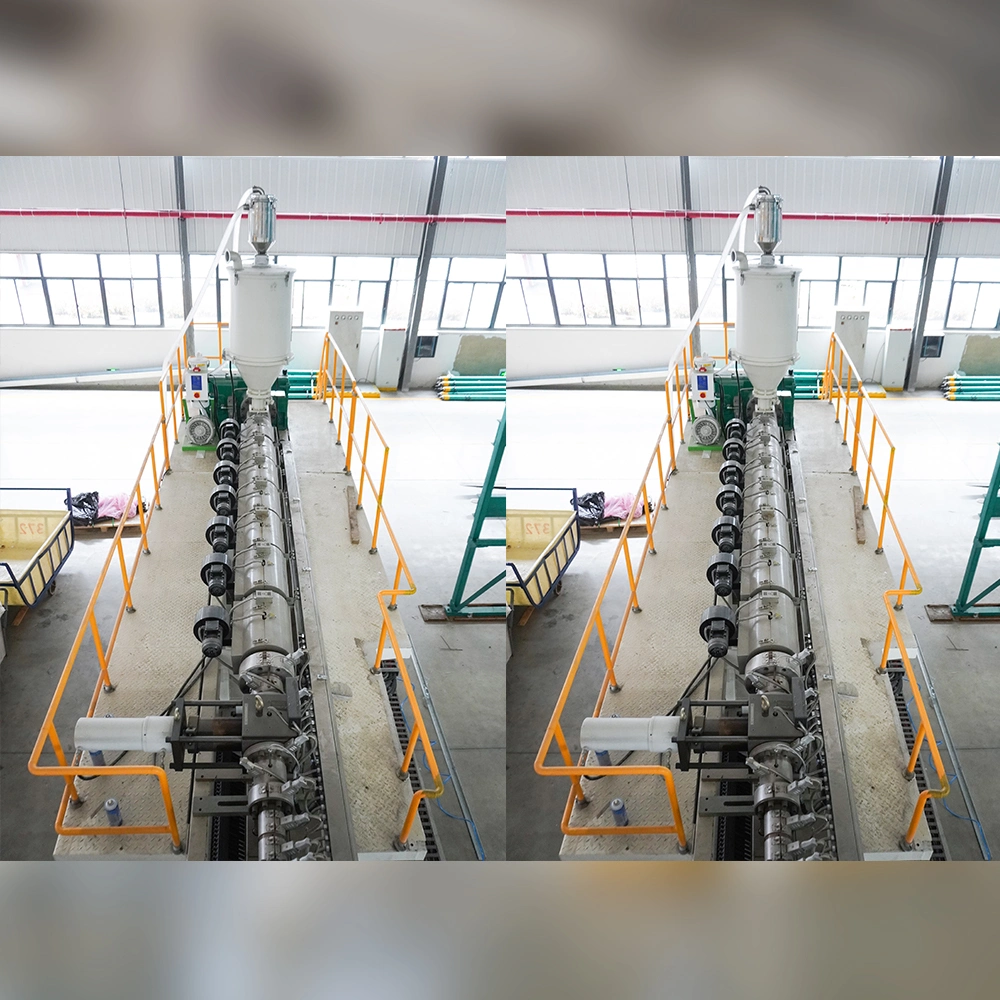

Lamination Composite Molding System

High molding cooling capacity and excellent temperature uniformity A film having a small roll unevenness and a uniform thickness can be obtained. Since the surface of the roll is molded and precision machined, high speed and stable operation can be achieved.

Double Station Unwinding System

The structure adopts a double-station servo unwinding device, which has high stability and maneuverability. It has a small unevenness and can obtain a very stable unwinding tension.

Products Application:

Prev: 3D Printer Filament Making Machine Peek PLA Filament Extrusion Line 3D Printer Filament Line

Next: 3D Printer Filament Extrusion Line PLA Filament Making Machine PETG ABS 3D Filament Production Line

Our Contact