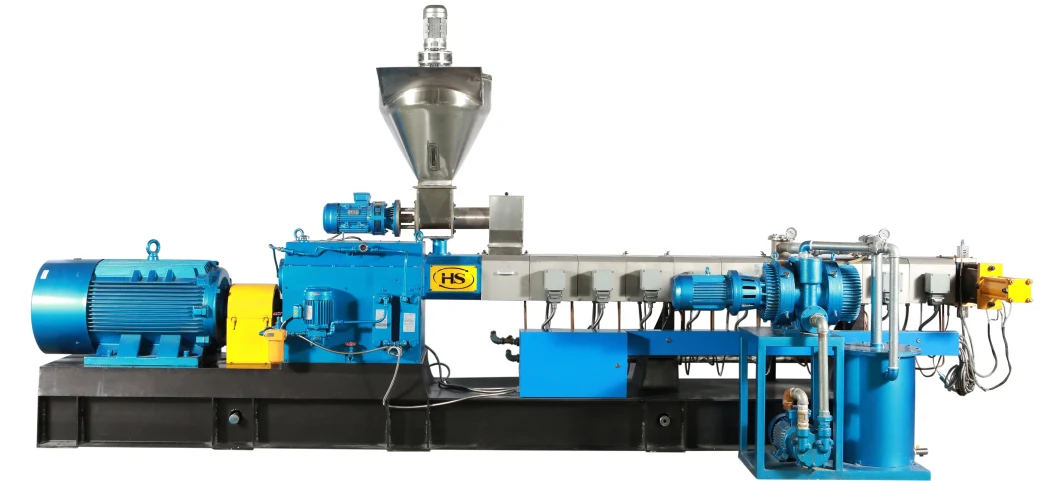

Tse-30 15kw 50kg/H L/D32-48 Plastic Pelletizing Extruder /Compounding Extruder/Lab Extruder

Technical Data of TSE-65B small parallel co-rotating twin screw extruder Application Special for waste plastic recycling

Description

Basic Info

| Model NO. | TSE series |

| Assembly Structure | Separate Type Extruder |

| Screw | Twin-Screw |

| Engagement System | Full Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Don′t Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Color | Customer Choice |

| Transport Package | Wooden Case |

| Specification | ce |

| Trademark | tse-kairong |

| Origin | Nanjing |

| HS Code | 87265100 |

| Production Capacity | Depends |

Product Description

Technical Data of TSE-65B small parallel co-rotating twin screw extruder

| Model | Diameter | L/D | Rotating speed | Power | Capacity | Weight | |

| TSE-65A | 62.4 | 36-40 | 500r/min | 716N.m | 180-250 | 4000kg | |

| TSE-65B | 62.4 | 36-40 | 600r/min | 716N.m | 200-300 | 4000kg | |

| TSE-65C | 62.4 | 36-40 | 600r/min | 875N.m | 220-350 | 4000kg | |

Application

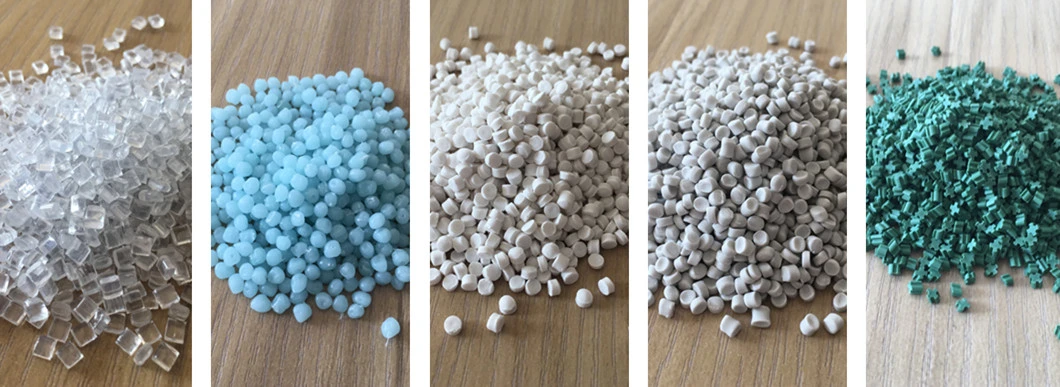

Special for waste plastic recycling, and convert to PP PE PET PS ABS PA PVC etc granules.

Two stage machine has better performance in recycling pvc.

Functions:

Plastics filling and modification, general and fibre color masterbatch, blending modification (rubber and plastic blending, plastic alloy), functional masterbatch, glass fibre or carbon fibre reinforcement, various cable material, reactive extrusion, handling after venting and dewatering, special material, powder coating

Characteristics:

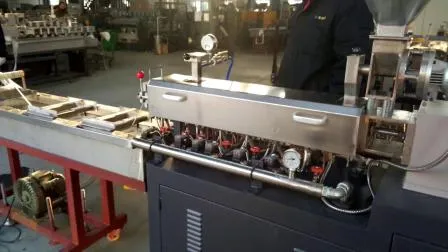

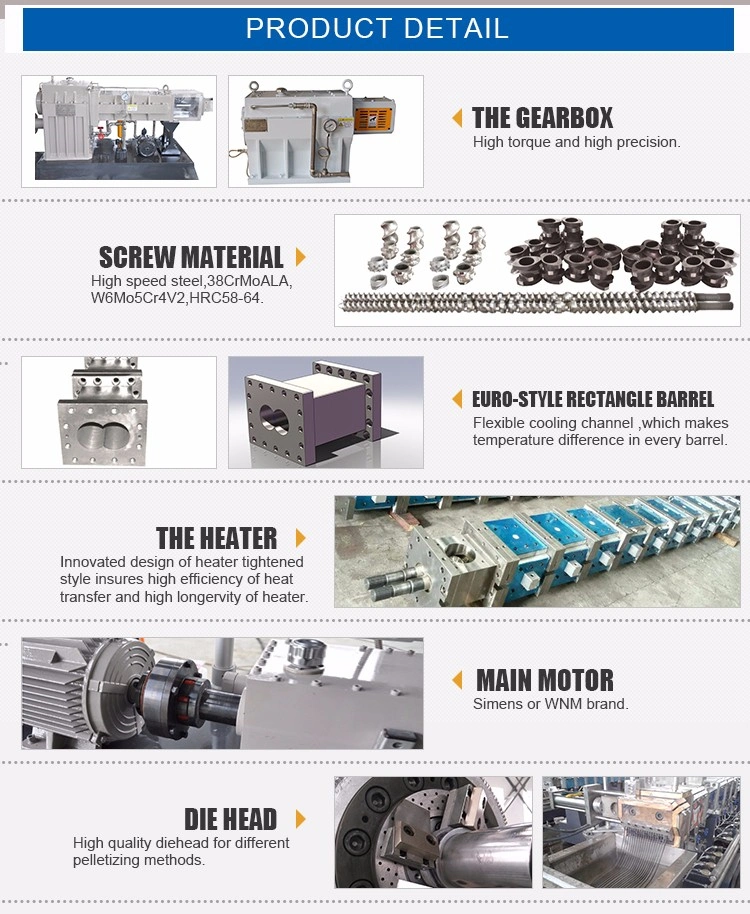

1, Modular principle design for screw configuration and barrel setup makes combination and cleaning convenient , also easy to adapt to customers' requirements .

2, Different kinds of pelletizing modes can meet specific material properties: water-cooling strand pelletizing, air-cooling hot-cut pelletizing, water-ring pelletizing, under water pelletizing, etc.

3, Screw elements and kneading blocks are made of high tool steel , with high corrosion-resistant and high wear-resistant.

4, Barrels are made of high quality nitrided steel , corrosion proof and antifriction.

5, Vacuum system fulfills devolatilization to ensure the quality of polymer processing.

Prev: Nanjing Mini Micro Compounding Desktop Small Lab Plastic Twin Screw Extruder Recycle Polymers

Next: Lab Plastic Polymer Compounding Parallel Co-Rotating Twin Screw Extruder Price

Our Contact

Send now