Small Lab Twin Screw Plastic Compounding Extruder 10% off

Product Application The continuous rotation of the screw repeatedly forces the material to turn, which helps to evenly m

Description

Basic Info

| Model NO. | XH-433 |

| After-sales Service | Life Time |

| Warranty | 1 Year |

| Raw Material | PE, PP, PLA, ABS, EVA, LDPE, HDPE |

| Screw | Double-Screw |

| Inverter | Inverter |

| Electromagnetic Heater | Cast Aluminum Heater |

| Automation | Non-Automatic |

| Computerized | Non-Computerized |

| Customized | Non-Customized |

| Condition | New |

| Color | Yellow or Customized |

| Power Supply | 3 Phases, 380V |

| Screw Diameter | 21.7mm |

| L/D | 40:1 |

| Output | 1-10kg/Hour |

| Cooling Mode | Water Cooling |

| Transport Package | Wooden Case |

| Specification | 3500mm(L)× 800mm(W) × 1650mm(H) |

| Trademark | XH |

| Origin | China |

| HS Code | 8477201000 |

| Production Capacity | 20sets/Month |

Product Description

Product Application

The continuous rotation of the screw repeatedly forces the material to turn, which helps to evenly mix and plasticize the material. Under the action of heating, mixing, shearing, plasticizing and compacting exhaust of twin-screw extruder, the material is plasticized into a uniform melt, and extruded under the twin-screw, through the nose of the circular extrusion. The material is cooled by a cooling water tank and then pelletized by a pelletizer to obtain plastic pellets. This experiment uses a cold-cut method of water cooling.Application range:Twin screw extruder has excellent mixing performance and can adapt to different types of processing of many material systems. It has been widely used in polymer processing, food processing, chemical products and other fields, especially suitable for the processing of various polymer materials.

1.General plastics, engineering plastics, elastomers and other materials mixing, mixing extrusion granulation

2.Blending modification and reaction of composites

3. High efficient mixing of polymer alloy

4. Polymer filling and reinforcing modification

5. Material dehydration, devolatilization and exhaust

Technical Parameter:

XH-433 Twin Screw Extruder | Applicable materials | PP, PE, PS, PET, TPE, etc. | |

Screw diameters | 21.7mm | ||

Screw speed | 0 - 300rpm | ||

Screw L/D ratio | 1:40 | ||

Output | 1 - 10kg/h (decide by formula) | ||

Cooling device | air/water cooling | ||

Cutting device | Granulator | ||

Power supply | 380V/50Hz/3 phases or Customerized | ||

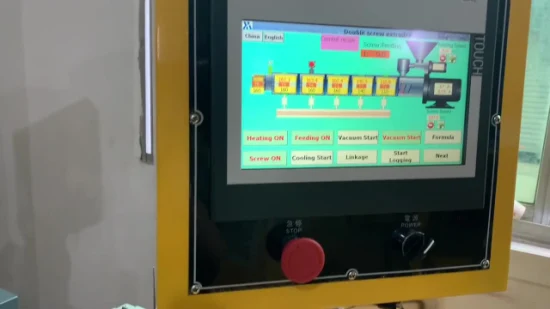

Control mode | SIEMENS Touching Screen PLC control | ||

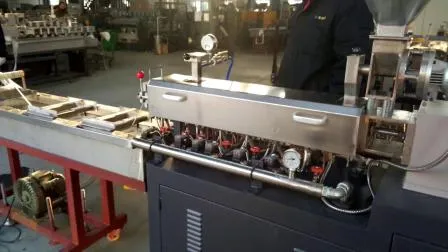

Machine Picture:

Siemens PLC Interface: Extrusion Die Head:

Pelletizer: Siemens Motor:

Pellets Sampes:

Our Team:

Display Room:

Our Contact

Send now