PP Raw Materials Twin Screw Extruder and Pelletizer Lab Twin Screw Extruder

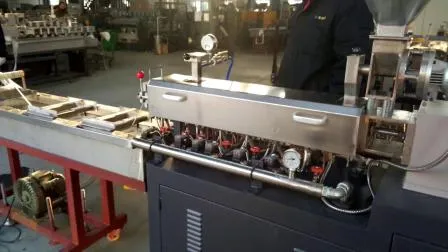

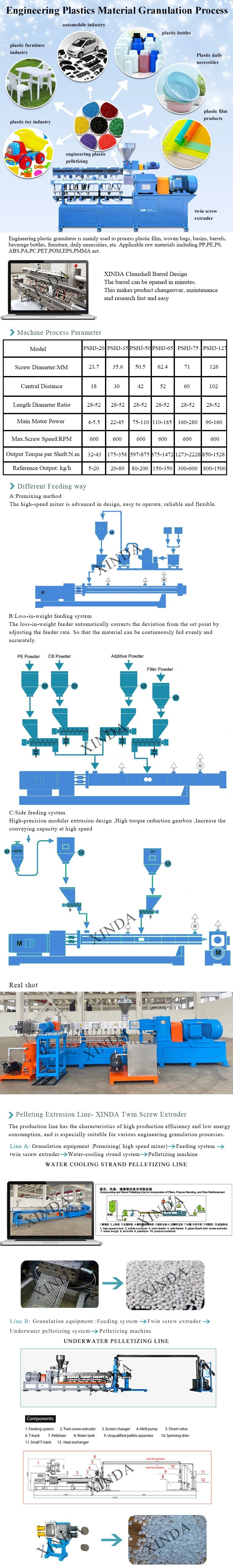

XINDA Double extrusion and pelletizing system apply to process plastic film, woven bags, basins, barrels, beverage bottl

Description

Basic Info

| Model NO. | PSHJ-35 |

| Automation | Automatic |

| Computerized | Computerized |

| Customized | Customized |

| Certification | CE, ISO9001:2008, QS |

| Condition | New |

| Capacity | 500-800kg/H |

| Applications | All Kinds of Polymer Mixing |

| Electric Brands | Siemens / Schneider |

| Control | PLC + Touch Screen |

| Extruder Weight | 800kg |

| Transport Package | Pallet and Wooden Box |

| Trademark | XINDA |

| Origin | China |

| HS Code | 84772010 |

| Production Capacity | 200sets/Year |

Product Description

XINDA Double extrusion and pelletizing system apply to process plastic film, woven bags, basins, barrels, beverage bottles, furniture, daily necessities, etc. Engineering plastic granulator is mainly used to Applicable raw materials including PP,PE,PS,ABS,PA,PC,PET,POM,EPS,PMMA ect.

Application

Color masterbatch/ Concentrates

High loading filler masterbatch

Hot-melt adhesive

Engineering plastics compounding

Engineered elastomers

Food

| Model | SJW-45(M) | SJW-70(M) | SJW-100(M) | SJW-140(M) |

| Screw Diameter:MM | 45 | 70 | 100 | 140 |

| Length Diameter Ratio | 15-25 | 15-25 | 15-25 | 15-25 |

Main Motor Power (KW) | 15-30 | 55-75 | 90-132 | 160-220 |

| Max.Screw Speed (RPM) | 500 | 500 | 500 | 500 |

| Reference Output (KG/H) | 40-50 | 150-200 | 300-400 | 800-1000 |

Prev: Easy and Simple Lab Parallel Twin Screw Extruder

Next: New Arrival Supplier Plastic Machine Lab Twin Used Dz75 Double-Screw Extruder

Our Contact

Send now