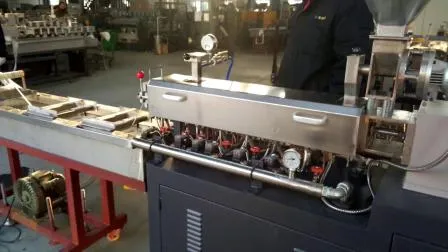

Easy and Simple Lab Parallel Twin Screw Extruder

Description

Basic Info

| Model NO. | SLG32 |

| After-sales Service | One Year |

| Warranty | 1 Year After Engineer Finished Installation |

| Certification | CE, ISO9001 |

| Power Source | Electric |

| Process | Mild Processing |

| Automatic Grade | Automatic |

| Application | Candy, Popcorn, Chips, Biscuit |

| Customized | Customized |

| Model No. | Slg65-III Slg70-II Slg85-II |

| Machine Name | Corn Puff Snacks Chips Making Machine Plant Pillow |

| Raw Materials | Corn Flour, Rice Flour... |

| Capacity | 100-150kg/H, 200-250kg/H, 300-500kg/H |

| Motor Brand | Siemens, China Famous Brand |

| Screw Materials | 38CrMoAl Alloy Steel, Which Has Long Lifetime |

| Corn Flakes Process | Mixing, Extruding, Flaking, Drying, Sugar Coating |

| Machine Material | Stainless Steel Food Grade Materials |

| Feature | Automatic, Low Consumption, High Quality |

| Technology | Extrusion |

| Inverter | ABB/ Delta |

| Speed Controlling | Inverter |

| Electric Parts | LG, FUJI, Omron etc |

| Loading Container | 20 or 40 Container |

| Transport Package | Woodencase |

| Specification | 2.5*1.0*2.0 |

| Trademark | JINAN FLD |

| Origin | Jinan |

| HS Code | 8438800000 |

| Production Capacity | 100pieces/Year |

Product Description

Product Description

High-quality, scalable results for product design and recipe or process testing Full process controls including comprehensive data recording allows easy analysis Portable - can be moved into production areas as a small batch production unit Dry powder and liquid feed systems for maximum flexibility

Brief Description of Laboratory Twin Screw Food Extruder:

Twin-screw lab extruder snack machine is our company research for universities, research institutes and large and medium-sized enterprises engaged in various extrusion , extruded maturation, extruded variability study omnipotent models. It has gone through four generations of improvements to adapt to cereals, potato starch, protein, chemicals, plastics, rubber and other raw materials are vastly different for a variety of experiments. Powerful,easy to operate and simply of parameters adjustment, test data accurate, easy maintenance.

2.Best Quality New Condition Food Lab Twin Screw Extruder Main Features:1) Simple structure in linear type ,easy in installation and maintation. 2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts. 3) High pressure double crank to control the die opening and closing. 4) Running in a high automatization and intellectualization,no pollution 5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine.

| Engine power | 5.5Kw | Second series L/D | 9.3/15/20.6 | Pressure scope | 0-30MPa |

| Engine speed-control | Frequency speed-control | Heating way | Heating ring | Pressure precision | 0.01MPa |

| Screw diameter | Φ30 | Cooling way | Water | Number of measuring pressure | 3 |

| Screw central distance | 26mm | Temperature scope | 20ºC-300ºC | Lubricate way | Oil pump forcing lubrication |

| Speed range | 500rpm-1200rpm | Temperature precision | ±1.0ºC | Oil pump power | 0.12kw |

| Screw mode | Building block-combined type | Number of measuring temperature point | 4 | Feeding Power | 0.18kw |

| First series L/D | 11.6/12.7/23 | Output | 10-25KG/H | Percent of water | 6%-60% |

Our Services

a. We can keep product design in the same level with internationally advanced technology consistently.

b. We have high diathesis staff and excellent processing equipment, and quality control runs through the whole production process from parts stock to the beginning of production.

c. We can guarantee customers superior quality machines up to design requirements and perfect working state.

d. Our technicians can also provide all kinds of relevant technology to make the food production clean, healthy and safe.

e. We will dispatch our technicians to your factory to guide you installation and commissioning work and training your operator.

f. We provide 1 year complete Guarantee and life-time maintenance service.

Packaging & Shipping

1. Daub coal oil on the surface of the machines.

2. Plastic film as the inner packing.

3. Standard export wooden case as the outer packing.

4. Train, ship or depend on clients' requirement

Company Information

Jinan FLD Machineryis a professional food machinery manufacturer in Jinan city shandong province China.Our company congregates an exceptional food machine engineering team, personal customer service center and highquality manufacturing capabilities have evolved exponentially,We are working hard on explore constantly not only in the research of extrusion technology, but also in food technics to benefit our clients producing newfangled food in their markets. It making us become one of the preeminent providers of reliable extrusion equipment world-wide.

We have through the years established good working relationship with some reputable organizations both at home and abroad with outstanding goodwill. We have a group of experienced experts and outstanding engineers who do provide the professional service delivery and installation. Based on the clients specific requirement, we also design and produce the machines to order.

FAQ

Q: How long is your delivery timre?

A: Generally speaking, it is 20 days if the machines are in stock. Or it is 25 days if the

goods are out of stock.

Q: Could you supply all the parameters about the machines?

A: Of couse. We are delighted to supply all the informtion that you want to know.

Q: How about the after sale service?

A: We will send our engineers to your factory for installation and training.

Contact with us:

If you have any questions about Multi-Functional Lab Expander Food Extrusion Machine , don't hesitate to contact with us.

Prev: Mini Lab Plastic PVC Extruder Plastic Filament Extruder Small Machine

Next: PP Raw Materials Twin Screw Extruder and Pelletizer Lab Twin Screw Extruder

Our Contact