Lab Rubber Calender Machine / Small Three Roll Calender Machine

Lab Rubber Calender/Small Three Roll Rubber Calender Used in Lab/lab calender machine Qingdao Create Trust Industry Co.,

Description

Basic Info

| Model NO. | CX-01 |

| Reducer | Hardened Gear Teeth,After Heat Treatment |

| Lubrication | Oil or Grease Automatic |

| Transport Package | in Wooden Case Safety Packing |

| Specification | ISO9001, SGS, CE |

| Trademark | CX |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 400sets/Month |

Product Description

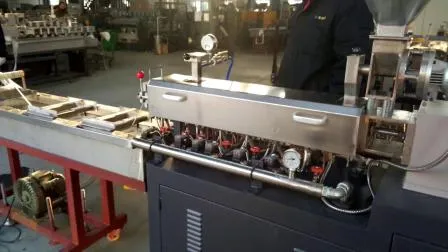

Lab Rubber Calender/Small Three Roll Rubber Calender Used in Lab/lab calender machine Qingdao Create Trust Industrymake high quality rubber machine, from materials to producing, we use the good quality material, complete management system, also excellent aftersale service, we hope to be one reliable factory for you!1. ApplicationRubberizing and fractioning of textile material, rubberizing of wirecord fabric, sheet, and counter plate(embossed) of rubber material, separation of fabric and film, as well as joint of multi-layer laminate film.2. General design:It mainly contains roller, rack, backplane, adjustment, device, transmission system, roller temperature control device, security device, lubricating device, etc.3. Features:The roller is made of chilled cast iron alloys, whose work surface has high hardness, wear-resistent and durable life. Steam, cooling water, and heat-conducting oil can pass into the rollers cavity, so that the working temperature can be adjusted in order to meet the technical requirements.Roll spacing can be adjusted both by manual or electric mode.Roller bearings lubricating can adopt drier oil or dilute oil.| Main motor power | 0.75KW*2 |

| Material appliable: | LDPE\HDPE\PP\PS\ABS\PC |

| Product thickness | 0.2-2mm |

| Product width | 0-80mm |

| Roll quantity | 3 |

| Diameter of roll | 120mm |

| Length of roll | 250mm |

| nip range | 0-5mm(adjustable) |

| linear speed | 0.5-19m/min(stepless adjustment) |

| Pull roll speed: | 0.5-20m/min(stepless adjustment) |

| Max. Roll Temperature. | 180 |

| Overall size:(L×W×H) | 825×700×1400mm |

| Safety standard: | CE certificate |

| Emergency stop: | Presss botton and pull rope |

| Notice: | LWM &water chilled chooseable |

Prev: Lab Film Blowing Machine Blown Film Extruder

Next: Lab Used Mini Single Screw Plastic Co-Extruder for Plastic

Our Contact

Send now