Lab Used Mini Single Screw Plastic Co-Extruder for Plastic

Description

Basic Info

| After-sales Service | Video Technical Support,Free Spare Parts |

| Warranty | 1 Year |

| Type | Profile Extruder |

| Plastic Processed | PE |

| Product Type | Granulating Extruder |

| Feeding Mode | One Feed |

| Assembly Structure | Integral Type Extruder |

| Screw | Single-Screw |

| Engagement System | Non-Intermeshing |

| Screw Channel Structure | Non Deep Screw |

| Exhaust | Don′t Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Keyword | Double Screw Extruder for Plastic |

| Core Components | Bearing, Motor, Pump, Gear, PLC, Pressure Vessel |

| Voltage | 220V 380V 440V or Customized |

| After-Sales Service Provided | Video Technical Support, Free Spare Parts |

| Capacity | 80-600kg/H |

| Bearing Brand | NSK |

| Power | 22kw-90kw |

| Screw & Barrel Material | 38crmoaia |

| Suitable Material | Mainly in PVC Industry |

| Application | PVC Pipes, PVC Profiles, PVC Granules |

| Transport Package | Film Packaging and Plywood Case Packaging |

| Specification | 2700*3800*2200 |

| Trademark | Bogda |

| Origin | China |

| Production Capacity | 100 Set/Sets Per Month |

Product Description

Product Description

Main Paremeters

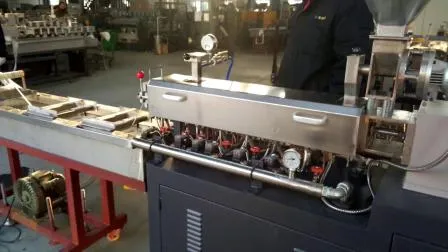

| Lab Mini Single Screw Plastic Co-extruder | |

| Screw Diameter | 25 mm |

| Hardness of Screw | HV900-1000 |

| Depth of Nitrogen Treatmen | 0.4-0.7 mm |

| Screw Straightness | <0.015 mm |

| Main Motor Power | 3KW |

| Electrical System | Siemens Contactor RKC Temperature Control Meter |

| Heating Method | Casting Aluminum Heater |

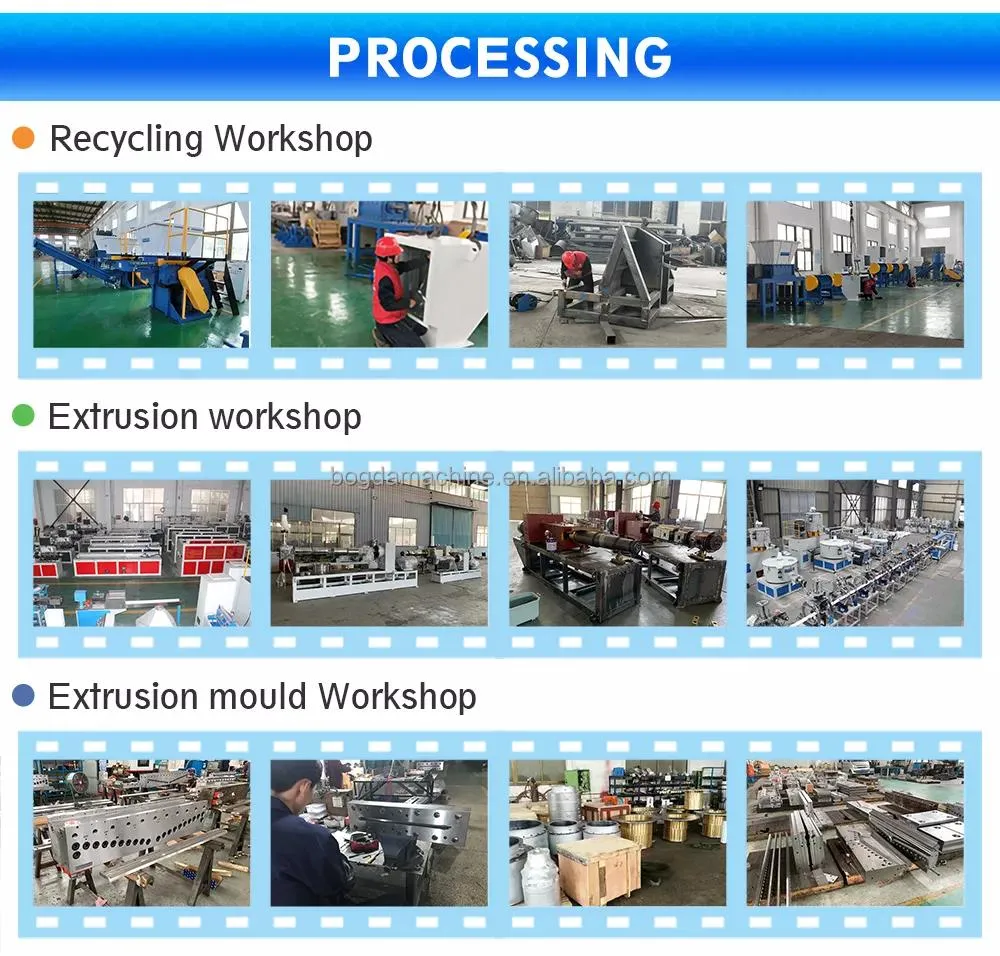

BOGDA Machinery Group is located in Europe and America (Hai'an) Industrial Park and Shanghai Fengxian (Hai'an) Industrial Park. It is a high-tech and innovative company dedicated to the research and development and manufacturing of plastic extrusion molding equipment. The company is people-oriented and innovative Development, with its unique corporate culture that has been brewing for many years, and the company's eager attention to global economic development, it has continued to grow with its majestic momentum and quick response, making itself a large-scale and highly anticipated industry in this industry.

Leading technology and excellent quality have been highly recognized by authoritative departments and markets. Products are exported to more than 110 countries and regions such as Europe, America, the Middle East, Southeast Asia, South America, Russia, Turkey, Italy, Poland, Brazil, Romania, etc. Deeply trusted and praised by customers, the company has many subsidiaries such as pipeline equipment, sheet film intelligent equipment, intelligent automation, and granulation equipment. The company has a high-quality talent R&D team and more than 20 years of experience in the industry. A team of mechanical and electrical commissioning engineers, as well as an advanced machining base and a standardized assembly workshop. More than 600 sets of high-end plastic extrusion lines are produced every Customer FeedbackFAQ

1. How many electric, water, air need for the machines?

BOGDA: technical department supply the whole layout for workshop details.

2. Can I operate machine if don't have experienced engineers?

BOGDA: (1) short-time engineers to customer company (5-15days)

(2) Year-time working as requirements

3. Any quality checking before shipment?

BOGDA: 100% confirm, run and test machines before shipment with quality certificate.

4. How long is the guarantee?

BOGDA: 12 months since the first day customer operates (except wear parts)

5. How can u help us when face some technical problem?

BOGDA: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

6. Where can we get spare part?

BOGDA: we choose International Brand that customer can find it in everywhere, such as Siemens, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Prev: Lab Rubber Calender Machine / Small Three Roll Calender Machine

Next: Laboratory PE PP Blown Film Machine/Film Blowing Machine Price

Our Contact